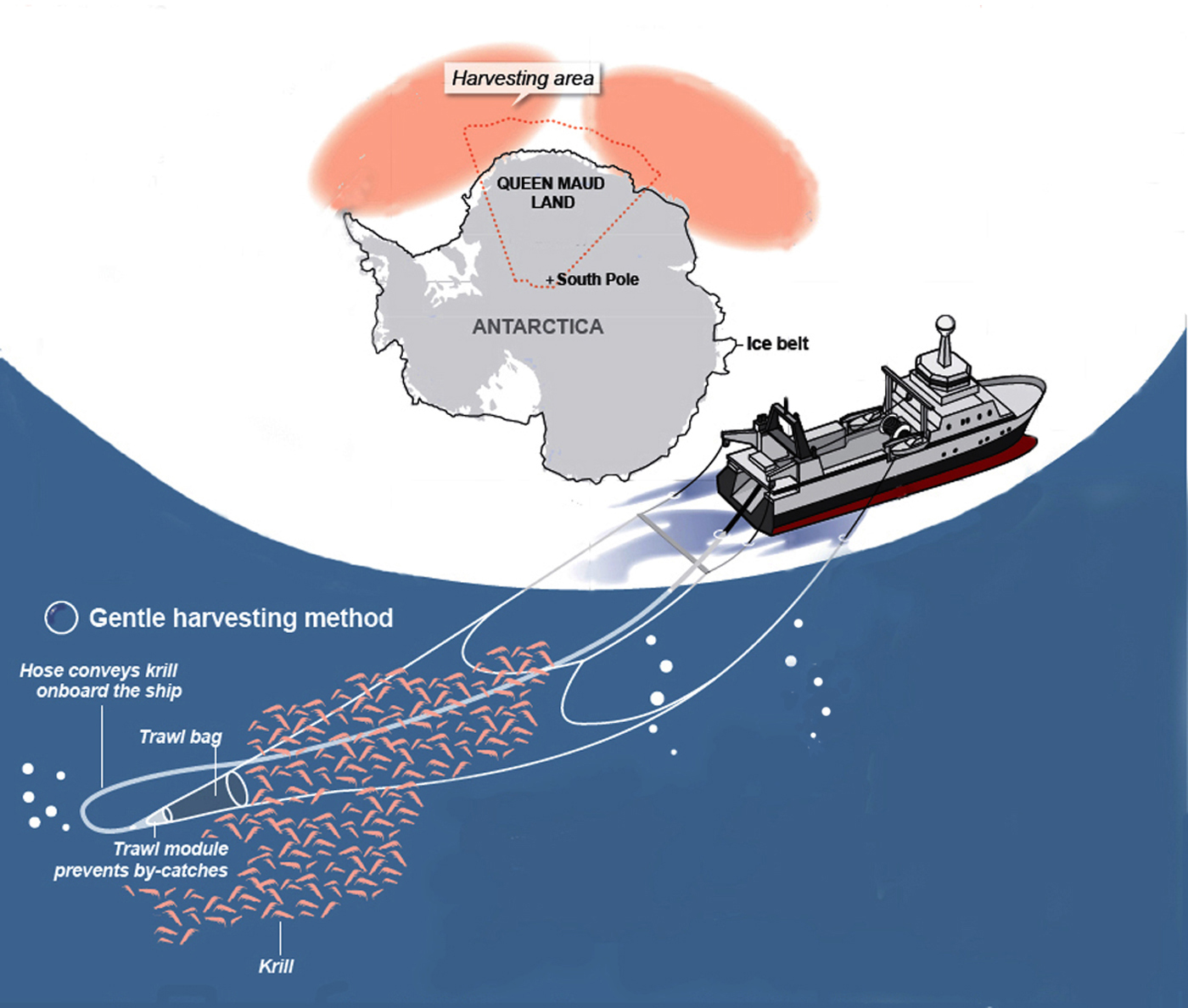

Eco Harvesting Technology

Eco Harvesting, krill harvesting technology, brings krill on board alive and processing begins immediately. The technology, using a specially designed trawl system and direct hose connection between the trawl and the vessel, holds a special mechanism that singles out unwanted by-catch, releasing it unharmed. Eco Harvesting causes minimal environmental impact and prevents the krill from enzymatic degradation. This is the key to preserve all the key nutrients in the end product.

Our suplier´s long experience in logistics and operations under extreme conditions is an important asset. It is also an mportant reason for why the company can operate in a sustainable way to offer krill products in the global markets.

Fresh first-step processing at the floating Life Science Factory

The Eco Harvesting systems enables to produce krill oil from fresh raw krill. Traditional trawling is unsuitable for krill harvesting. The Antarctic krill holds very potent digestive enzymes, and it basically self-destructs before it can be processed.

Eco Harvesting means the equipment stays under water hile a continuous stream of water flows through the hose, bringing the live and fresh krill directly onto the factory vessel. This allows for processing of fresh raw material directly onboard the floating Life Science Factory, which again means bioactive components are retained for superior product quality.

In contrast, krill harvested via traditional trawl-anddump methods, undergoes rapid decomposition, which significantly depletes its nutritional value.

In fact, because it is environmentally clean in its original form, no purification or distillation is required. Furthermore, the immediate on-board processing of Krill prevents decomposition and degradation and protects the nutritional integrity.